Bourns engineering and product development expertise includes a broad array of standard, custom and enhanced analysis, modeling and test capabilities. Using these advanced tools enables us to speed product development and meet specific market and application requirements. It also helps us prevent manufacturing and component defects to ensure the highest level of product quality.

Bourns uses the following sophisticated analysis, modeling and test resources in the development of its industry-leading products:

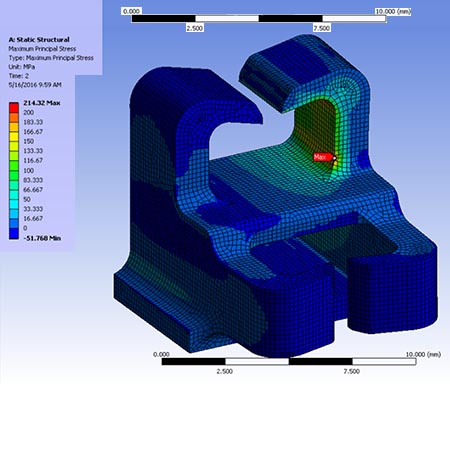

Mechanical Loading Stress Analysis

For stress analysis a geometrical description of the structure is used, properties of the materials.

Mechanical

- Simulation – provides an accurate and efficient method to determine if structural designs meet desired requirements

- Deflection and structural stress – accommodates different physical loading conditions by understanding the bending stress and moment, shear force, deflections, and slopes of structural beams

- Finite element analysis – proves component function and solves problems of over- or under-engineering performance by predicting a product’s reaction to real-world elements such as heat, vibration and fluid flow

- Mold flow analysis – reduces costs by ensuring proper tooling design, using virtual modeling to optimize characteristics such as pressure profile, time-to-fill, or melt temperature before a costly steel mold is cut

- Thermal analysis – ensures the highest reliability by modeling thermal performance, controls, and protection during all phases of product performance

- Static and dynamic flow – determines the most concise injector flow measurements by ensuring optimal pressures both when fluid is at rest and flowing

- 3-D models – comprehensive, detailed models help increase innovation and reduce design and manufacturing time, enabling faster prototyping and simplify design modifications

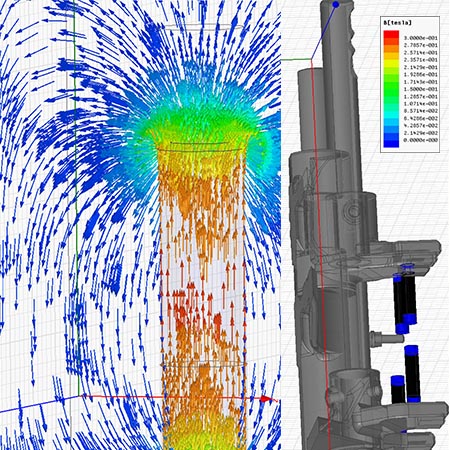

Magnetics Analysis

Field Strength & Direction Plot

Electrical

- Simulation – ensures reliability and quality by visualizing the complex interactions between hardware, software and network connections

- Spice models – simulates circuit designs to ensure robust performance under a wide variety of modifiable operating conditions

- Monte Carlo analysis – enables educated, data-driven design and manufacturing decisions through simulated probabilities for risk, financial impact, and overall costs ranging from the conservative to the extreme

- Electro-magnetic field analysis and modeling – simulates electric fields caused by charges and distribution of voltage, assuring performance and compatibility of system components such as cables, capacitors, and high-voltage equipment

- Lightning/Surge Debug and Test CapabilityBourns has surge generator/measurement equipment in the US, UK, Central America, and Asia that complies with Telecom (ITU-T, ATIS, Telcordia) and Industrial (IEC/UL) safety standards. Being an active participant in these standard bodies, Bourns can guide and help customers debug/rectify any potential problems before end products undergo expensive standard body testing.

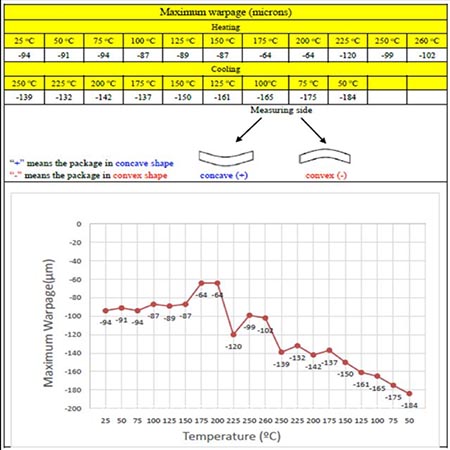

Shadow Moiré Comparison

Epoxy #1 + LCP Lid (Note: After 260 °C curing, epoxy #2 unit flatness (149 µm) is smaller than Epoxy #1 epoxy unit (184 µm).)

Manufacturing

- DFM guidelines – allows for the following smart, structured design principles to help reduce costs and mitigate difficulties in manufacturing, strategic planning and solving problems in the earliest phases of design. Essential as about 70% of manufacturing costs are related to design decisions while production accounts for about 20%

- Statistical analysis for ANOVA, Regression, DOE, Multivariate, Control Charts, Reliability/Survival – employs statistical methodologies to increase design success by using the broadest range of analysis tools to ensure clear understanding of related differences under a diverse set of variables

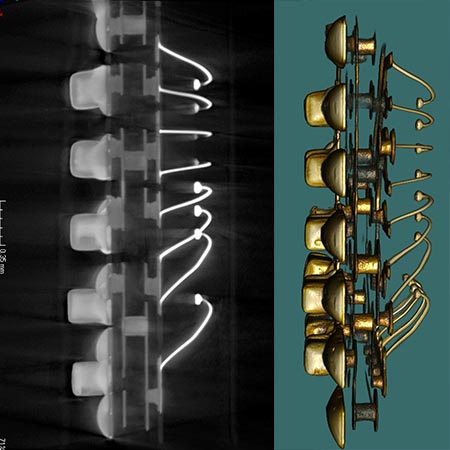

3D X-RAY with CT Scan

Also known as industrial computed tomography, X-rays are anylized in conjunction with CT scans.

Failure Analysis

- 3-D X-ray, CT scan – illuminates the critical fit between components, enabling a highly accurate view of product geometries

- SEM EDX, WDX – provides quantitative information on a product’s chemical composition, troubleshooting performance using techniques that provide high energy resolution and low background noise

- DSC, TGA, TMA, DTA, HPLC, FTIR, XRD – characterizes material composition using the widest array of analytical tools, such as calorimetry, thermal analysis, diffraction, chromatography and more

- Shadow moiré – fast, robust data modeling measures pixel position down to <1 micron using a proven, full-field optical technique